Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Izanami" with Nickel Magnesite gemstone handle

Jay Fisher - Fine Custom Knives |

|||

New to the website? Start Here |

"Izanami" with Nickel Magnesite gemstone handle |

||

There are many components that bring a fine custom or handmade knife to its pinnacle of style, use, and completion. Though the first view is of the blade and handle, the bolsters, guard, pommel, and fittings are just as important to the construction and fulfillment of the piece. Understanding how all these components work together, their materials, how they are finished, mounted, displayed, oriented, and completed is essential to the knife maker. These features and components are just as important to the knife client, owner, or user, and, along with the blade, set the overall strength, artistic tone, or tactical value of the knife.

On this page, you will find the basic introduction to the handle and fittings. Please take a few moments to familiarize yourself with the knife handle and fittings in detail before moving to the more detailed specifics and examples in the pages that follow:

An old knifemaker once told me: "The blade makes it a knife, but the handle sells it." A rather quaint way of looking at knives, I think, but somewhat accurate. The handle is the link to the hand, the tactile, textured lock to the human form that assures a military combat or tactical knife will function with the user. It's also the aesthetic, beautiful fit to a collector's or knife owner's hand that demonstrates the maker's skill and care and accentuates the blade style and shape, anchoring the artistic concept of the knife. The handle is often the canvas that sets the artistic knife maker's work apart from others; it may well be the distinction that sets the value, purpose, and function of the knife. For modern knife makers, we have access to more elaborate and wide-ranging handle materials than ever before in history. The handle may truly customize a knife, it may make each knife creation unique. Its form, shape, texture, color, materials, arrangement, and embellishment all work together to complete the knife and allow the knife to complete the owner's needs. The handle, with associated fittings, is not simply something to grab.

Hi Jay,

You don't know me but I just wanted to say THANK YOU for the wealth of knowledge about knives and all things

related (and some things unrelated, too) that you share freely on your website! A lot of people may not agree

with all your opinions, but I think it's great how much you are willing to share about what you've learned

over so many decades of practical knifemaking experience. Your website is a very valuable resource. As a

hobbyist, I often look up your info about handle materials.

- Mark Ou

The earliest knives were simply blades of splintered rock, and it probably didn't take long for early man to cut himself trying to hold on to a sharp piece of flint, obsidian, or chert. He realized along the way that some real leverage might be possible if he could just figure out a way to make that chunk of rock sharp on one end, and dull on the other so he could hold it. The other problems were that the rock was heavy, and the material was a limited commodity. He probably figured out quickly that the blade was entirely different than the handle. One end needed to cut, the other couldn't. Sticks were easy to grab, and so were bones and pieces of antler, and they seemed to hold up pretty well, so all he needed to do was marry one to the other in permanent fashion. So a little of that pine sap and some tiny strings from a plant or tough gut strings of a dead animal, and voila! It wasn't pretty, but that could come later.

The first metal blades were a wondrous invention. Smiths were so fascinated with the metal that they decided metal handles were the answer. Metal handles worked pretty well, except the metal was heavy, and it was cold to hold on to in the winter, and the metal itself a precious commodity, better suited to the blade only. So, back to the sticks, horn, bone, ivory, and leather. These were once-living things that were warm to the touch, softer than the steel, comfortable to hold onto. But they dried up, shrank, and cracked, absorbed greasy hand stain, blood, and filth, then got slippery. Unfortunately, there were no reasonable alternatives available, so a practice of re-handling blades was necessary. The finest blades were adorned with rock handles, gemstones that were carved and often inlaid with precious metals and other gem. They survive to this day.

Modern man still makes metal blades. He is still concerned with the limitations of early man's knife handles. The new materials he has available, and the new adhesives, sealants, and chemical treatments make a huge variety of knife handles feasible and practical. There are plastics now, and rubbers, epoxies, and composites. There are new methods of attachment, new hardware, dyes, shaping tools, and pressure-treating and finishing processes. Perhaps the most important inventions and refinements of the last 50 years are: adhesives, abrasives, and the computer. The modern professional knifemaker uses them all.

There are hundreds of books on knives, swords, and edged weapons history, and I encourage you to explore this fascinating field. By the way, the combative side of the field is called hoplology. We can focus on the particulars of what early man has learned, and reveal how he now copes with the same problems of the blade-handle issues.

It sounds like a simple thing. Add some lines and length to a drawing on paper, and you have a handle. Additionally, you must consider the leverage ultimately applied to a blade, the grip geometry, the shape of the human hand, the stock size and cost, and the angle of the handle to the blade. And there are many other points, most of them discussed on this page.

The knife's intended use determines to a great degree the shape and size of the handle. If a knife is to be used in delicate, highly controlled cutting, then the handle is usually much larger than the blade. This allows a great degree of control of the knife; for example, look at a surgeon's scalpel. It has a long, narrow handle and a very small blade. Conversely, if a knife is to be used as a heavy tool, with aggressive cutting and light chopping, it has a large blade and a smaller handle to keep the weight in the blade. The knifemaker walks a fine line between balance, overall weight, length, width, and gripping geometry. The knife handle must protect the user, offer a secure grip, increase the leverage applied to the blade, increase and adjust the handle length, bolster or strengthen the whole knife, rigidly attach the handle components (scales, pieces, inlays, etc.), be comfortable to hold, resist exposures, compounds, and fluids that will degrade it, offer longevity to match the blade, be cost effective, weight balanced, and above all, beautiful! That's a lot to ask, and the experience of the knifemaker plays a key role here.

Sometimes patterning out the profile in acrylic or aluminum is the only way to find out how a knife will feel in the hand, and how the blade will project in use. I think a lot of factory knives are designed by people who don't use their hands to make a living, and that is where the problem starts. They might design from a computer program, or perhaps they might use models that are closer to pens and pencils, as those instruments are more familiar in their daily use. Also, many designs come from foreign countries where the people are physically much smaller-framed and have more modest attitudes. I think this attributes to style overall. Another major contributing factor is that this saves the manufacturer substantial money on materials and supplies to machine them. You may see very large, voluminous handles in cheap, light, hardwoods or plastics. Often, the decision of how to make a handle rests largely in the manufacturing process and cost factors, and less in the handle size, shape, or usefulness.

There is also a large difference in human hands. Some people have small hands, some larger. Only a custom maker can size the fit of the hand to the knife client. I've included a special page here to size the hand width to the knife for custom orders.

How to know if a knife handle can be custom made to fit your hand? Take a good look at the maker or company that is handling the knife. Do they have several hundred patterns available to fit your needs? Do they have dozens or even hundreds of different materials available in hardwoods, horn, bone, and ivory, manmade materials or gemstone? Will they custom design a knife suited just to you?

Usually, this means a clear object barrier between the sharp blade and the hand. A fully guarded knife does this best, absolutely defining and preventing the hand from going forward. It's drawbacks: it is large, sometimes heavy, and best suited to large knives and swords. Guards sometimes offer huge areas to embellish, which may compliment an investment grade collector's knife. A smaller version of the guard becomes a quillon, the part that stops the finger(s) from sliding forward. The quillons can be incorporated into a finger groove, they can be on the rear bolster, locking the hand to the handle, and they can even be incorporated into a sub-hilt, mid-bolster, or central quillon, which helps lock the hand into the handle.

An issue with large guards, quillons, sub-hilts and physical barriers within the handle arrangement is that all hands are different, and there is no universal shape or design that will always be comfortable to all hands. Mid-handle divisions may also restrict the knife owner from holding the handle in a reverse or non-traditional grip style. More pieces within the handle add more weight, more mechanical complexity, and more cost.

How much complexity is too much? How about a folding guard? I saw a humorous attempt on a public posting at making a rather elaborate Bowie/Sword fit into a machete-sized sheath. The maker thought it would be a good idea to have the guard fold backward into the hand of the person holding the big knife. This would allow the piece to fit into the large sheath. Problem here? Well, if a knife is a real knife, a guard would never fold, as that would render it pretty much useless. Also, the injury that could happen to the hand gripping the handle is a sobering reminder that the purpose of the guard is to protect, not collapse and fold over onto the hand! What was surprising was how many other knifemakers thought this was a great idea! It goes to show how few knifemakers actually make working knives in modern times. If the piece was just for display, why not make the blade fold too, in about five pieces, then you could stuff it in a pants pocket and do away with the whole sheath...

A guard or quillon of some fashion is almost always recommended on a medium to large knife. The movement, physical forces, and weight of the knife require that some form of protection is given to stop the hand from sliding forward onto the blade. Though you may see an omission of quillons, finger grooves, or guards on a very few of my knives, these are very light and small designs not intended for heavy use. Once a knife design is of substantial size (larger than a typical folding knife), I believe some form of guarding is necessary. I do have a few smaller patterns that omit the protection.

I question any medium-sized knife style that, as tradition, omits a quillon, guard, finger groove, or any device that stops your hand from sliding right onto the cutting edge. (this is the traditional puukko, puuko, or puuka in Finnish) What were those Finns thinking? When I see one of these knives, I wince at the thought of a forefinger sliding forward onto a razor sharp blade. My Finnish knife enthusiasts assure me that this type of knife is only used as a tool, and that the protection is not necessary, and some have claimed they know of no accidents involving this type of handle. If, however, you look up the term "Tommi Puukko" you'll discover that the guy who studied at Fiskars designed a puukko for fighting, and it looks like every other puukko blade and handle arrangement, slick and dangerously unguarded. So, although the knife is considered a tool, some are considered weapons. Perhaps this is an artifact of the requirement that in many of the Nordic countries, knives as weapons are outlawed. If you study deeper, you'll find that some of the newer puukko designs are incorporating a finger groove and bit of a quillon to offer a bit of hand protection.

Grip security is a complex subject. It's partly based on friction, which (believe it or not) is a mysterious facet of physics that is only now being seriously studied on the molecular level. Friction alone is not the determining factor of the knife handle. If it were, the handle would be covered with rough sandpaper, insuring your grip. The truth is, there is a careful balance of friction, comfort, and intended use of the knife that must be met, balanced with materials and exposure.

The handle shape has more to do with a secure grip than friction, because there is a large variety of exposures that the knife handle and hand may encounter. Sweat, grease, water, oils, salt spray, humidity, dirt and debris, and even gloves all effect the hand to handle bond. Since so many of these are out of the control of the knife maker, the handle shape takes a lead in how the knife feels and works in the hand.

The handle needs to feel good going into and out of the hand as well. A well-shaped handle also helps the hand orient the cutting edge in the dark or without looking at the knife. The human hand is amazing, it can adapt to a variety of shapes, but not all of them are comfortable to maintain, rigid yet movable, strong, yet with a light touch. Some shapes are more suited to a tactical grip, locking the hand to the knife so the user can apply great force, some grips need to be light and delicate, such as a skinning knife or caping knife where the knife is used more like a surgeon's scalpel. It is a very touchy-feely thing!

You may have noticed a good deal of finger rings on my professional, combat, and tactical knives, as well as collector's, user's, and specialty knives. The reason for a finger ring is simple: it's security. When a finger is laced through the ring, it increases the security between the knife and hand many times. This can be off-putting to some, who may have heard of the many dangers of metal rings of all kinds. I, too, have heard these horror stories: how a man playing basketball left his ring finger hanging on the basket after being ripped from his hand when his wedding ring caught the metal frame, how a parachutist left his ring finger hanging in the plane after the jump. I'm sure there are many more, and you probably have your own versions. I've personally never met anyone who lost a finger to a ring, but I can imagine that it's a concern. There is a huge difference between a wedding band that tightly grips a finger and does not easily come off and a finger ring on a knife. A knife finger ring is typically one inch in diameter on the inside, which allows an easy insertion and removal, but is still very secure.

The finger rings I use are designed for the index finger, so you can tell by looking at the knife if it is typically held in a traditional or a reverse grip. If a knife is held in a traditional grip, the finger ring is at the blade-handle junction, if it is held in a tactical reverse grip, the ring is at the butt of the handle.

You don't often see well-made finger rings on knives. I believe it is because of the greater expense in the width and thickness of the steel required, and the additional cost of machining and finishing the interior and exterior of the ring. The ring can not simply be a drilled hole through a section of tang. Its placement is critical, and is usually not along the center of the axis of the handle. So, wider stock must be used to accommodate the ring design and construction and accommodation for additional steel geometry to support force transfer between the ring and the tang. The ring must have thin enough walls to allow a finger and parts of the hand to wrap around it, yet be thick enough to be strong. This can be a problem on a ring at the handle butt, because the tang must also be tapered for strength-weight control. So a thick piece of steel stock, at least .250" or greater must be used. An additional concern and expense is finishing. The ring must not merely be beveled, it should be rounded, smoothed and often polished on the inside and outside, so that the hand is not injured or abraded by sharp or rough corners. It takes a lot of time and effort to get this right, and that is why you don't often see well-made finger rings on knives.

The use of a finger ring is a personal preference. If the knife blade is caught in a piece of machinery while a finger is laced through, it could lead to a serious accident. But what is your knife doing near a piece of machinery anyway? Many clients are convinced that the additional security is worth it, and do not want the knife to leave the hand. Others do not prefer this design. Either way, it is the knife client's responsibility and choice, and I make the knife according to their specific needs and requests.

Since finger rings are more common on tactical and combat knives, please take a look at those by entering my Military and Tactial Knife Portal page.

From the trench knife to sci-fi flicks, we've all seen knuckle guards and D-rings designed to protect the hand by fully sweeping around the exposed fingers, or to double as a set of brass knuckles for defense. While this may be a viable application, there are some points to consider when designing, incorporating, or ordering this type of handle fitting arrangement for a knife.

Please consider carefully this option and style of hand guard and handle for any knife. I'm not setting out to discourage your selection of this type of handle, only to illustrate some points and limitations that you may not have considered.

To increase leverage to the cutting edge, the handle must accommodate bearing down. That force is usually applied through the spine of the knife, the thickest metal that supports the back of the blade and extends into the handle. Often, the thumb is the mechanism that applies that force, with the palm supporting the movement. Contrary to popular beliefs, a large knife cannot apply more cutting force, unless you swing it through the air and take advantage of its mass to apply force to the cutting edge (it then becomes chopping force, completely separate from controlled cutting). It's a small knife, with a large handle that can apply the greatest controlled cutting leverage. This is why wood carving tools and knives have huge handles and tiny blades. That relationship also lends itself to great control of that small force area. Just look at the design of a surgeon's scalpel. Large, long handle, tiny, thin blade. Most surgeons are intimately aware of this relationship, and balance in general, consequently; many of my fine clients are docs.

The handle increases the length of the tool overall. As a blade gets longer, the lever-applied force to the handle-blade junction increases, particularly when great stresses, such as chopping and sawing, are applied to the blade. So the handle design must be thickest just behind the ricasso, the generally flat area behind the grind, and in front of the front bolster or guard. The bolster also must reinforce this area, and that is it's main function: to bolster.

Other than a skeletonized handle, the lightest weight handles are a small group of hardwoods and some stabilized woods. Woods like maple (rock, fiddleback, bird’s eye, or curly) are very hard and durable and very light weight. Some stabilized burls (like redwood or box elder) are very nice, beautiful, serviceable handles. Plastics like Micarta® phenolic and ironwoods and rosewoods are usually heavier.

The lightest is, of course, a skeletonized handle (where there is no handle material, only a milled tang), but not the most comfortable for heavy field use. I try my best to balance the handle weight with the blade length, style, and use. A lightweight handle isn't always the best bet, as the knife can be more substantially balanced and "settled" into the hand if it has a heavier handle.

Why so few bolsters on knives? This is a great question, and one that should pop up a lot more often than it does. First, understand that bolsters are used on full tang knives and sometimes on folding knives, so this topic does not include hidden tang, rabbeted tang, or pin tang knives, and mainly involves full tang knives. The reason to make a knife full tang is (or should be) strength. Full tang knives are unquestionably stronger than any other type of blade-to-handle arrangement, so strength is already in the maker's conception and conversation. Yet, few makers today use bolsters on their knives.

There are some serious reasons for this and doubly serious reasons that it should be carefully considered by the modern knife client. A knife is simply less without bolsters. Less strong, less durable, less robust, less overall. Like most handmade and challenging craftsmen's pursuits, the reason to not use bolsters are many, and they are omitted for the benefit to the maker manufacturer, to the detriment of the knife, and the disadvantage to the knife owner and user.

By reading these points, it will be clear, from this professional knifemaker's perspective, as to why bolsters are not often seen and the strangely damaging contemporary practice of omitting these critical features:

You may see the same, tired arguments against bolsters, posted repeatedly on forums, discussion boards, and in conversation. What are the specific points and how do they fit into the conversation?

Purpose? The bolster does exactly that; it bolsters or strengthens the critical areas of the knife, mainly the blade/handle junction and the butt of the handle. There are many different arrangements, but strength is what the bolster is about. It also aids in supporting the mounting of the handle material (I dovetail nearly all my bolsters, locking in the handle scales for rigidity). The bolster also offers a fine area for embellishment (engraving, etching or inlay of materials and gemstones). The bolster reduces lateral flexion by offering more area for bedding and adhesion of dissimilar handle materials. The bolster also aids in gripping the handle, and sometimes offers wider area than the blade for the thumb to rest and a quillon to prevent the hand from sliding forward onto the blade. The bolster can offer an area to exert pressure onto the knife, and strengthen the butt for easy removal from the sheath. The bolster may also act as a pressure point, a skull crusher, an impact area, or a tactical persuader. The bolster can strengthen the area of the lanyard attachment point, reduce stresses on the handle, and offer a corrosion-resistant surface for the hand to grip. It may strengthen mechanical areas and devices, such as in a folding knife or tongue and groove mechanism. It can also aid in retaining, bedding, and protecting handle materials, particularly end grains on woods. It also critically protects the most vulnerable areas of bonding stress at the adhesion points of the scale-to-tang. I wrote about this above, that the tensile strength of epoxide adhesives is low, and the bolster critically and mechanically reinforces this very location.

Attachment? The bolster attachment is important, for in order to work, it must be bonded to the blade in a complimentary and permanent fashion. Some knifemakers solder bolsters. This is a weak union, as soldering only adheres the surfaces of the metal to each other. One of the most important things I've learned over the years is that order for dissimilar materials to be bonded, they must first be mechanically secure, and second to that is adhesion by glues, solder, brazing, and finally welding. It's all about the mechanics. Incidentally, I've never had a failure of any fitting on any knife, in over 3000 knives made and sold and in use for over 30 years.

Integral bolsters is a name that makers have assigned for a knife that does not have attached bolsters or guard; the fittings are instead milled along with the blade out of one solid piece of stock. On first glance, this seems like a good idea, but it is limited in these critical ways:

So why is this touted as some great advantage and why is it done? Because it's easier than actually making independent bolsters, matching them, and attaching them permanently to the knife! It's because, in knifemaking, the most common culprit of misdirection is that the machine that creates the knife is limited in operation and use. Yes, I said machine because if a knife has integral bolsters and guards, it is created by machining operations, namely Computer Numerically Controlled milling machine operation, what is typically used to create this type of knife. Most of these knives are never "handmade," no matter what the maker may tell you. He is not standing at the grinder holding the knife in his hand slowly working through the overburden of thick stock that needs to be removed to create the integral knife; he is clamping the blade stock in a CNC mill, and letting the computer carve away the material that is not the finished knife, under a splash hood with automated control. If he's old school, he may use a Bridgeport Toolroom knee mill to do this, but still, it's a machine operation where the machine is control, not the human hand.

This is faster and easier than making a knife by hand, even if hand-machining (grinding). There, I said it. Yep, it's a decision of lack of quality, in effort to save money and time for the maker, and is not of any advantage to the client. Just as in many areas of this trade, a manufacturing decision is somehow touted as being advantageous to the knife owner. This sad practice happens frequently in this trade, and I'm determined to uncover this type of misdirection, and misconception, no matter how long it takes. You are taking your precious time to read this; you deserve to know the truths that most other makers (and all manufacturers) won't tell you.

Please help to stop wives' tales, knife myths, and misconceptions in our trade through education.

For the reasons listed in the previous topic, it is often and mostly beneficial that the bolster or guard stock be made from a different material than the blade. Here are some of the bolster and guard materials I use, and the reason they're used.

Brass: Brass is an old standard for knife bolsters and guards, and is an alloy of copper and zinc. Some guys aren't even interested in a fitting that isn't brass. Brass resists decaying corrosion that would "rust" it away, and brass develops a passive patina that inhibits further corrosion. It polishes easily, it has an initial warm, inviting color, and it engraves easily. It solders easily, and brazes well, both advantageous on milled-through guards. It's good for knives made for people who have nickel allergies.

Disadvantages: Brass tarnishes easily, is relatively soft and scratches easily. It is not as strong as other materials, and has a distinctive odor. Some of these limitations can be controlled by using naval brass, a more corrosion-resistant and tougher brass. Knives with brass bolsters simply require more maintenance, polishing, and waxing. Brass can also stain and darken leather sheaths, textiles, and some clothes, particularly in wet environments. In time, brass in contact with leather in even moderately humid environments will form a destructive, horrible green product of corrosion (copper carbonate or copper chloride) that will stain everything it touches and be very difficult to remove.

Nickel Silver: Also called German Silver, this material is a type of white brass. Like brass, its base is copper, with zinc, and the addition of usually 18% nickel (it has no silver in it; the name refers to its color). It has a pleasant, warm silvery color with a hint of yellow, is more resistant to scratches than brass, and is corrosion resistant to atmospheric water and organic compounds. It is easily soldered for work on guards. It's relatively strong. It engraves well.

Disadvantages: It is not as hard as ferrous metals (steel and stainless steel), and has a definite yellowish tint compared with the bright, silvery blue of a stainless steel knife blade. People with nickel allergies should avoid it.

Low Carbon Steel: Also called plain steel, low carbon steel, or mild steel, this is non-tool steel, or soft steel. It is used mainly for bolsters and guards that will be engraved, and is the traditional material for historic engravings with a deep history in firearms engraving use. It engraves deep, clean, and easily. Brass and nickel silver (being soft) are not as capable of retaining high detail in deep relief because they wear away, scuff and scratch easily. Deep relief is the engraving where the background is relieved and blackened. Low carbon steel is tougher and harder than brass or nickel silver, so resists scratches more. Good for people who have nickel allergies.

Disadvantages: Plain steels will easily and readily rust if not meticulously and constantly cared for. It will corrode quickly, particularly when in direct contact with the hands, so a coating of microcrystalline wax or light oil and regular maintenance is necessary to prevent this. Plain low carbon steels are high maintenance bolster materials, even more so than brass! If pits are allowed to form, they may be impossible to remove without regrinding and refinishing. I rarely use this material for bolsters any more, as there are better choices.

Martensitic Stainless Tool Steels: The same stainless steels that are used on the blade can be used on a separately attached bolster or guard. For example, a 440C blade can have 440C pins and bolsters. The stainless is harder, tougher, and more corrosion resistant than any of the previous listed materials. It polishes well, and the color matches the blade. It is very resistant to scratches.

Disadvantages: The stainless tool steels are very hard to engrave, and most engravers won't even touch them. They do not reach their full stain resistance until they are hardened and tempered. So corrosion resistance, while good, is not as high as the blade (if the blade is made of the same stainless tool steel), because the bolsters must be mounted after heat treating. Though I've used these in the past, I do not use or recommend this bolster material; there are currently better choices.

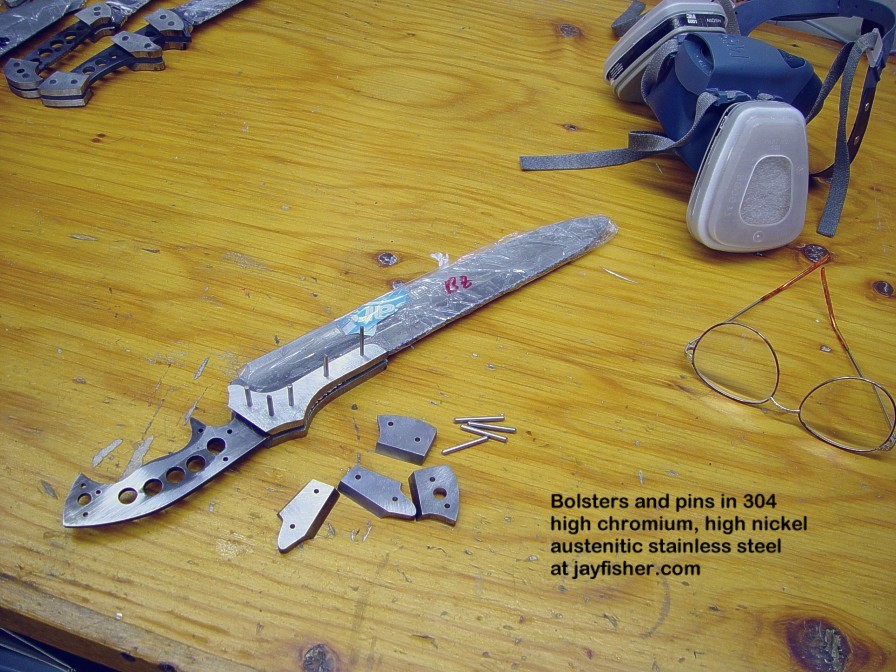

Austenitic Stainless Steels: In this group of steels, I use 304 stainless steel, and I consider this the best bolster, guard and fitting material in the stainless alloy steels. This is not a martensitic tool steel, and has little carbon but does have as much as 20% chromium and 11% nickel. It is hard and very, very tough. The color of the steel matches the hardened stainless blade steels beautifully. It is completely impervious to any substance that might corrode it, except very strong exotic acid blends and electrical currents. This material stays the way it was finished for decades and decades; nothing touches it. It very resistant to scratches. How tough is it? 304 is the same as 18-8 stainless steel that is used on stainless bolts, screws, and fasteners. How corrosion resistant is it? This is the same stainless that is used in the finest stainless steel cookware. I believe it is the premiere bolster, guard, and fitting material to use on the highest value, toughest, most durable knife handles, period. The reason you don't see it more often is because most makers can't or don't want to work with it: it's hard, extremely tough, and difficult to machine. It's very difficult to engrave. So they opt for the softer, cheaper, and easier to work stainless steels (like 416 and 410).

Disadvantages: 304 stainless steel does not machine easily (my problem, not yours). It does not engrave easily, and most engravers will refuse to attempt to engrave this tough, hard material. But I do, and my clients love what I get. It also costs more, mainly for the effort and machining.

Important note: In my opinion, it is absolutely the finest bolster material available.

400 series Free Machining Martensitic Stainless Steels:

Here we're talking about 410, 416, and 420 stainless steels. They are stainless steels, polish well, and are used by a lot of knife makers. They have some of the characteristics listed in the "Martensitic Stainless Steels" paragraph above, and have some distinct differences. The most important is machinability. These steels are not as tough and wear resistant as 304, which is difficult to machine. These steels have much lower chromium than either 440C or 304, which means a markedly lower corrosion resistance, particularly when not heat treated, lower than the blade if the knife is made of most of the martensitic tool steels used for knife blades. So, they can corrode easier. The reason most makers use these steels is because they are easy to machine, not because of any other reason. So the choice to use them is of convenience to the maker, not the knife owner.

More Disadvantages: I never use them because the alloy content creates a slight yellow cast to the color, which does not match most stainless steel blades. If the knife will have a stainless blade and bolster or guard, why not make it match in color? Most importantly, 400 series stainless steels MUST be hardened to reach their full and expected corrosion resistance. Bolsters applied to a knife blade are never heat treated, so corrosion resistance is less than optimum. Even if the bolsters were heat treated, both of these steels are inferior in corrosion resistance to 440C, ATS-34, or CPMS30V (S30V). These 400 series stainless steels can not even approach the corrosion resistance of 304 stainless; they are a completely different type of steel. Manufacturers of these400 series steels claim they are 'heat treatable stainless steels only used where corrosion is not severe." Why use stainless steel fittings at all when they are more likely to corrode, more so than the blade? Now you can understand why I don't use them and why I don't recommend them either. More in the section below; 304 vs. 410, 416 stainless steels.

Copper, Silver, Mokume Gane, Diffusion Welded Metals, Damascus: these are constructed metals, specialty metals, and all are selected for a unique appearance. A client asked how the Mokume Gane is made on the knife in the photos below and here is my detailed response:

The metals are chosen that have a similar base, in this case, nickel silver and copper which both have a copper base. The sheets of metal are meticulously cleaned, as any contaminants would prevent fusion. Even a fingerprint would cause problems, so cleaning is an involved process, including scrubbing with pumice and strong chemical degreasing. The sheets of metals are arranged and clamped in a "stack" in a steel framework. The clamping is very, very tight. The clamp and stack are place in a nitrogen-filled electric furnace, and brought to just below the melting temperature of the metal and held at that temperature. Because the expansion of the copper based alloys is greater than the steel clamp, the tightness increases even more! During this time, the molecules become very excited, and electrons cross from one sheet to the adjacent, and diffusion welding takes place as molecules start to share electrons. The stack is held at this temperature for a while, while fusion takes place. After the stack and clamp cools, the clamp is removed, and the stack has become a solid billet. The billet can be drilled, filed, cut, and heated and forged to create variation in the pattern. After the forged piece is cut, drilled, and mounted to the knife with zero-clearance pins which are peened, it is then sanded, polished, and finished. The surface is lightly etched and colored with potassium sulfide to bring out the differences in the metals. The surface patina is waxed for protection.

Not all patterned, damascus, and other metal bolsters require such an involved process, and all are chosen based on their applicability to the knife's artistic value and arrangement. I've used many different types of bolster, guard, pommel, and fitting materials, and each has its own characteristics, advantages, and disadvantages. A sampling of those materials is below:

The choice of bolster, guard, or fitting material depends on the knife design, the intended use, and the artistic arrangement of the handle components. There are many more bolster materials, and I'll add examples as I can.

The consideration of the client is the top priority for me.

Clearly, there is no advantage to using 410, 416, 420, and 303 stainless steel in knife fittings, bolsters, and guards apart from making it easier for the knife maker to machine. This is detrimental to the knife owner or user, as the fittings are less corrosion resistant, and less tough.

The section above on various stainless steels used for fittings was brief, and I think it's important to go into greater detail about the distinctive differences between several steels used in knife fittings. In knifemaking, unfortunately, there is a propensity to make what the knifemaker wants and less often what the client desires. This is something I've written about before, and in this section, I'll try to be clear about how a simple metal choice demonstrates this.

Please understand that I, too, make the kind of knives I prefer to, but when I do, I'm considering the final knife client, the man or woman who will own the knife, use the knife, cherish the knife, sometimes for generations. Because the consideration of the client is the top priority for me, I try to offer the best possible materials within the range of the client's choices, budget, and idea.

While some people prefer the look of brass, copper, or mokume gane (detailed above), most modern knife clients prefer stainless steels, and for good reason. Stainless steels are chosen for the bolster and fitting material for the same reason a stainless steel is chosen for the blade. They are corrosion resistant.

Older knives that have carbon steel bolsters, fittings, and devices are a constant source of complaint and worry; a bit of rust quickly grows into a pit, a pit deepens underneath, the knife can quickly become ruined. Please also consider that the metal underneath the bolster, guard, or fitting, (the part of the fitting you can't see) can be corroding out of sight. The best way to combat this is to have corrosion resistance built into the material.

Most engravers love carbon steels. Used extensively in firearms, carbon steels are soft and easy to engrave with plain gravers and tools. They hold high detail, and can look great when they are first finished and presented. They can be darkened with over-the-counter gun blue. They easily and quickly react with their environment and exposure, since they are not corrosion-resistant in any way. So they have to be oiled and protected. Waxes don't work well on carbon steel engravings, since the wax will dry and turn white in the cuts. So, typically, oil is the protectant. Oil soils, stains and attracts dust and dirt, and eventually dries up, so the knife owner has to be vigilant with his new engraved carbon steel. More about oil vs. wax on my Knife Care page.

Years later, the worry continues; the knife owner can't let his guard down for a single month, or even after a single handling, since an errant fingerprint will eventually become rust. Human hands are acidic, moist, and sometimes carry compounds, elements, and salts that will encourage and accelerate corrosion, and on an engraved knife fitting, this can be disastrous. The handle is where the hand is expected to grip the instrument, yet knifemakers continue to ignore the long term corrosion potential of interaction with the human hand.

Most engravers won't even consider engraving stainless steel. There is an old saying in our field, that engravers won't charge for engraving stainless steel, instead, they will pay you to take the stainless away! This attitude exists because of the tough, hard, and durable nature of stainless steels, and the difficulty of engraving them. Again, easy may be good for the engraver, but it doesn't bode well for the owner, who will never stop worrying about corrosion setting in on his carbon steel engravings.

This isn't just limited to carbon steels, brass can also corrode. Ever see what happens to rifle and pistol cartridges stored long-term in a leather bandolier, bag, or pouch? The green oxide is not only destructive, it's toxic.

In order to eliminate corrosion as a concern, stainless steels are used in knife handle fittings. Stainless steels form a passive oxide on the surface at the instant they are exposed to oxygen, so are passive by nature.

The degree of passivity varies markedly among stainless steels, and that is the focus of this section. The choice of stainless steel types for a knife fitting material affect the corrosion resistance, appearance, and long-term value of the knife immediately, and more importantly, in use over time.

If you look around the internet and read the choices and discussions about stainless steel knife fitting materials, you'll see several players come up over and again. These are the same stainless steels that you'll see for sale by the knifemaking supply companies, suppliers that depend on the hobbyist and part-time knifemaking factions. You'll also see these stainless steels in use by boutique shops and manufacturers.

Forum moderators (unskilled watchdogs of anonymous postings) will simply claim, "use 416 stainless for bolsters and guards." Most of these people don't have the knowledge or record to back up their claims, they've just made a few knives and claim to know what's best for other unskilled people. They have plenty of time, though, to sit fat at their computers and make thousands of posts...

The steels they incorrectly recommend are 410, 416, and 420 stainless steels. Makers will swear they are the best for knife fittings, and there are a lot of knives made with 400 series stainless steel fittings, and there is a reason for this. Unfortunately, the reason is not because they are the best steels for the job.

I'm committed to making the best, so for comparison and explanation, I'll detail why don't use or recommend the 400 series of stainless steels. I know that knifemakers reading this will wince, some will go on to try to defend their use, and like other parts of this site, they'll decry my comments. Others will change their minds, start to use the premium material, and their clients will like it so much that the makers will never go back to using the inferior stainless steels. This is simply what I know in service to thousands of knife clients over four decades of knifemaking at the time of this writing.

400 series stainless steels are martensitic stainless steels, by composition and classification. They are made to form martensite. If you have read my Heat Treating and Cryogenic Processing of Knife Blades page, you'll understand how important martensite is to tool wear. Briefly, martensite is formed when carbon is locked into the crystalline lattice structure; it is a strained and carbon-rich allotrope that adds hardness to the metal.

High martensite is great for a knife blade, but has no bearing on fitting material. Fittings are not expected to need extremely high wear resistance, since the fittings don't cut anything. The fittings are expected to have corrosion resistance, because that is where they are held by the hand.

Knife blades that are martensitic are heat treated, hopefully through complex and sophisticated cryogenic processes, in order to bring out the highest wear resistance, toughness, and corrosion resistance of the steel. What? Corrosion resistance?

This is the problem with using 400 series stainless steels in knife handle fittings. CORROSION RESISTANCE is the reason to use these steels in the first place, yet, in order to reach their maximum corrosion resistance, they must be effectively and professionally heat treated. These 400 series steels, like all martensitic stainless steels, do not reach an acceptable level of corrosion resistance until they are hardened and tempered. All foundries, machinists, metallurtists, and suppliers of these stainless steels will clearly disclose this fact! They must be heat treated to be truly corrosion resistant.

You might think this is minor, but here's a clear comparison to consider: 400 series stainless steels that are in the condition they arrive from the supplier (fully annealed and spheroidized) will usually darken, dull, and rust if you leave a water drop on them to dry at room temperature. The same water drop on hardened and tempered 400 series steels will not discolor. I've seen this over and over, it's clear, simple, and easy to understand.

This also explains why, in order to qualify as Food Contact Safe, all 400 series stainless steels used on knife fittings absolutely, positively must be heat treated with an "appropriate post-weld heat treating process," as specified by NSF §7.1.

Let's be very clear on this. 410 stainless steel contains 11.5% chromium, and this barely classifies it as a stainless steel, having minimal aqueous corrosion resistance. The Food Contact Safety standard absolutely requires appropriate heat treating process on this steel; there is no exception. The same is true for 416 which only contains 13% chromium. The same goes for 420 stainless steel which only contains 13% chromium. These steels must be properly heat treated before use as knife blade fittings for any food contact; it's the standard.

A side note here: a lot of uneducated knife makers and enthusiasts claim that D2 isn't a stainless steel. The truth is that D2 contains more chromium than 410 stainless steel, and the same people will undisputedly claim that 410 is a stainless steel. Then, they go on to use 410, untreated, on their knife fittings, and tell their clients that the fittings are highly corrosion resistant. If you are a knife buyer or owner, you need to know this. Both D2 and 410 must be properly heat treated to produce the maximum corrosion-resistance.

Heat treating these steels doesn't mean merely heating them up with a torch and quenching, it means a sophisticated regime of treatment, hardening and tempering, with cryogenic process, and I'll reassert the claim that this is never done with fittings.

Some makers—after reading about this section—may even claim to harden and temper their bolsters, guards, and fittings, but they are not doing this. Want proof? Put a drop of lemon juice on the bolster and leave it there for several hours and see what happens. At the very least, if a maker is claiming that he hardens and tempers his bolsters, ask him what his process is, what his final temper is, and why he has chosen it, and watch him squirm.

Unfortunately, there is a lot of misinformation in our trade, a lot of hyperbole, misrepresentation, and outright lies. It would be nice if this wasn't the case, but it is so, and the client deserves to know the technology, reason, and condition of what he buys.

If a knifemaker does harden and temper these 400 series steels for fitting materials, he is wasting his time because at their very best, they are substantially less corrosion resistant than 300 series austenitic stainless steels, and by a significant margin. Why not just use the highly corrosion-resistant 300 series stainless steels? Then, the maker doesn't have to worry about heat treating them at all. Why not offer the highest corrosion resistance possible to his clients, knife users, and owners? Why not offer him a "zero-care" high chromium, high nickel stainless steel that will hold its finish indefinitely? Remember that the metal underneath the bolster, guard, or fitting, the part of the fitting you can't see can be corroding out of sight. Why not have the highest corrosion resistance possible built into the alloy, since corrosion resistance is the reason for choosing stainless steel in the first place?

This failing is done because it's much easier and cheaper for the knifemaker, manufacturer, boutique shop, or factory. Knifemakers quickly learn that machining (cutting, drilling, grinding, sanding, and finishing) metals that are high in chromium and nickel is a difficult process. Many makers are too lazy, in a hurry, unskilled, or unknowledgeable about the machining, grinding, and finishing process of austenitic stainless steels. If you read between the lines in discussions and on maker's websites, you'll see that many makers don't want to work with the more difficult, and tough austenitic stainless steels; they want it to be easier. This is the same attitude they take with the superior high chromium martensitic hypereutectoid high alloy stainless steels for knife blades. It's just too difficult and time consuming to use them in a blade, so they settle for lower alloys or carbon steels.

As I've written before on this website, "faster and easier" is not a reason to be a knifemaker at all, yet guys are constantly trying labor-saving tricks that are of no benefit to the knife owner, user, or client. Simply put, 410, 416, and 420 series stainless steels are chosen for fittings because they are stainless steels that are easy to machine and work, not because they have any advantage to the knife owner, particularly long term or in wet or corrosive exposures.

The 400 series stainless steels that I list are easier to machine because they are not particularly hard or tough in their annealed condition. They are not as tough and not as corrosion resistant because they are low in chromium, the hardest metal on the periodic table, and they are low in carbon. 410 stainless has only about 12% chromium, and 416 stainless steel has about 13% chromium, and neither have any nickel at all.

Compare this with 304 stainless steel that has 18 percent chromium, and 8 percent nickel, and it will make sense that in any condition, 304 stainless steel is substantially more corrosion-resistant than the 400 series. This also makes 304 stainless much more difficult to machine, because the alloy is extremely tough. Toughness is good in fittings, particularly in thin guards where extended geometric forms would be better suited to be tougher, and less brittle and likely to break.

The most important thing is corrosion resistance, where the hand contacts the fittings, and the reason for choosing stainless in the first place. Just know that 416 stainless steel has the easiest machinability of any stainless steel, which is great for the maker, but not so good for the knife owner.

One of the contributing factors aiding in machinability of these steels is the addition of sulfur. Sulfur is not considered a beneficial alloying element; it is considered an undesirable impurity in the alloy! This is why sulfur is limited to low content in steels. Sulfur weakens steels; causes brittleness, and makes steels with high sulfur unweldable. Sulfur is put in steels to make them easier to machine and that is the only reason it is used. While 410 is generally low in sulfur, 416 can be extremely high, depending on the manufacturer. This is why forum posers and moderators recommend 416; it's easy-peasy to work with and is stainless (kind of) in the untreated condition.

Another factor is that sulfur can add a distinctive yellow cast to stainless steels; easily seen when compared to high alloy, martensitic stainless steel blades. This is the reason not to use 303 stainless steels in knife fittings; it is a high sulfur variant of 304, made to be more machinable than 304. Again, the option of easy comes to mind. By the way, 303 is less corrosion-resistant than 304, so the only reason to use it is to make it easier on the maker and manufacturer, and of no benefit to the knife owner. It also has a slightly yellow cast compared to 304, not the bright bluish chromium appearance that fine high chromium tool steels have.

Clearly, there is no advantage to using 410, 416, 420, and 303 stainless steel in knife fittings, bolsters, and guards apart from making it easier for the knifemaker to machine. This is detrimental to the knife owner or user, as the fittings are less corrosion resistant, and less tough and a bit yellow.

Knifemaking is not about easy; it's about making the best knife for the guy who holds the handle. This is why I use 304 stainless steel for the fittings on nearly every knife I make. This same steel is also used to make nearly all stainless steel nuts, bolts, and fasteners, and nearly all stainless steel kitchen equipment and facilities, as well as nearly all medical stainless steel equipment, since it is so remarkably corrosion resistant. 304 absolutely qualifies as a Food Contact Safe material.

What about nickel allergies? Some people have these, so it bears consideration.

There was a great study about nickel allergy and contact in the stainless steel category. The study demonstrates how some stainless steels break down and others don't.

"The main conclusion is that low-sulfur stainless steels like AISI 304, 316L or 430, even when containing Ni, should not elicit nickel contact dermatitis, while metals having a mean corrosion resistance like a high-sulfur stainless steel (AISI 303) or nickel-plated steel should be avoided."

—"Nickel Release from Stainless Steels," Haudrechy P., Mantout B, Frappaz A, Rousseau D, Chabeau G, Faure M, Claudy A in Contact Dermatitis (1997)

Boom! Another reason to avoid high sulfur stainless steels!

In the National Sanitary Foundation (NSF), Food and Drug Administration, (FDA) and the American National Standards Institute (ANSI), there is a specialized rating called the Food Contact Substance (FCS). In order for a steel to be FCS rated, it must, by definition, contain at least 16% chromium. Since no one is doing a deep cryogenic treatment for bolsters and fittings:

It seems to me that the optimum FCS rated knives in performance, safety, and corrosion resistance are 440C with 304 stainless steel bolsters and fittings. Now you know another reason why I make them this way!

If it's not a bolster, don't lie by calling it one.

A real bolster strengthens the handle, a bolster

that is not made of metal weakens it.

Knifemakers find out rather quickly how difficult it is to make bolsters; you know that if you read the previous sections on this page. Bolsters are small pieces of metal, often thick (or they should be) and they are difficult to cut, machine, mill, grind, sand, finish, mount, and polish. Makers also find out that they do not finish or blend well with softer handle material, leading to unevenness in the form. The process of finishing them often digs out the softer material right at the edge of the harder bolster material and this is obvious to the knife client, and it looks very bad and feels worse. So, rather than conquer this difficult challenge to make an even, substantial, and worthwhile metal bolster, years ago, guys started replacing the bolster metals with softer materials, like acrylic plastics, G10, Micarta, or wood. This is a cheap, shoddy effort and it's time that someone actually spoke up, described, and shined a bright light of truth on this type of handle. This is a shortcut on the part of the knifemaker, and an indicator of how he's made the knife, sheath, and accessories overall: with shortcuts in mind.

At first glance, you might suspect this as just another choice, something more colorful or visually interesting than the metal bolster, but let's get some clarity here.

A fake "bolster" is actually a "weakener," and a sign of a weak

effort on the part of the knifemaker overall.

The knife client should wonder at what other shortcuts the maker has

made.

There are a lot of discussions about the preferences of bolster materials among knife makers, and a lot of discussions about the stainless steels. I believe this is because most modern handmade custom knives are moving away from nickel silver, carbon steel, and brass in favor of stainless steels. The reason is because of value and longevity. Stainless steels do not need babied, polished, waxed, or tended to regularly. They are tough, hard, and very wear resistant. They can add value to the knife. Few people want to worry about handle maintenance, scratches, scuffing, and corrosion. If a knife is to be very tough, made of very durable materials (like tactical combat knives) additional durability is paramount.

Discussions on the Internet demonstrate that most makers do not like to use 304 stainless steel, one of my most favored bolster materials. Their reasons are because 304 is difficult to machine, hard to finish, and nearly impossible to engrave. They say that if a knife maker is making a knife to be engraved by an engraver, most engravers won't touch the stuff because it's very difficult to work with, cut, and finish. Guess what? They are correct!

To me, this is what makes 304SS so valuable. I work with it more than most makers and I absolutely love it. By the way, this is the same stainless steel (18-8) that is used to make stainless steel bolts, screws, and fasteners, so it is very durable and tough. Yes, it's hard to drill, mill, grind and machine and ultimately engrave. But as a professional knife maker, I'm a machinist and metalworker by definition, and that does not stop me from offering the best material to my clients; they expect that. Specialized techniques are required, and this is in the skill requirements and practice of a modern metals worker. I'm even welding 304 SS fittings and components, and I am excited by the beauty and appearance. 304 is not a material for the timid, but in my opinion, it is the best for the application of bolsters and guards when you want stainless steel, and I believe it has the longest term high value as well as the lowest care factor.

What are these other guys using? They're using the 400 series stainless steels, which are martensitic, and easier to machine due to alloy components. But the most important limitation for 400 series stainless steels is that they do NOT reach their full corrosion resistance until they are hardened and tempered, and that is never done. So to sell the properties of corrosion resistance on stainless steel bolsters when using 400 series stainless steels is only viable if the bolsters and fittings have been heat treated, and I've never heard of anyone ever doing that. Even if they were heat treated, they would not reach the corrosion resistance of S30V, 440C, or ATS-34 knife blades. Also, even if and when they are heat treated, they cannot come close to the corrosion resistance of 304 stainless steel. See the details about this in the section above: 304 vs. 410, 416, and 303 Stainless Steel

I've always believed that dovetailing bolsters is the absolute best way to make them, and I'm all about offering the very best. When a bolster is dovetailed, the face that is against the handle scale is angled over the handle scale. This accomplishes several things.

Why don't other makers and manufacturers use dovetailed bolsters, what do they use, and why? I've seen plenty of bolster arrangements in my decades in this business, and here's how it typically goes: A new maker realizes he wants to bolster a knife, for the obvious reasons listed in the topics above. So he starts with straight, flat bolsters, like small squarish blocks attached to the tang. These look coarse and simple, and the handle scales are not locked, but simply adhere against the squared-off face. Flexing the knife in normal use creates fine cracks and separations in the bolster-to-scale junction, and the adhesive (typically epoxy) will crack a this point. So the maker chooses one of several options: either improve bolster design, or make a thicker tang that won't flex (making the knife handle-heavy) or eliminate bolsters altogether because they are just too much trouble. This third option, eliminating bolsters and leaving the tang too thick seems to be the mainstay of current knife construction, and this is sad. Makers figure it's just not worth the trouble, so they don't make bolstered knives at all.

What about other arrangements or bolster geometry? Every maker has tried curves, sculpting, shaping, rounding, and contouring bolster faces and scale-side edges, but runs into problems and limitations. Since curved bolster-to-scale junctions can not be dovetailed (you can't fit the handle underneath!), then these areas are left squared-off, that is, ninety degrees to the flat of the tang. This is a result of the process (milling and shaping with a machine). Even though they may be curved, they fall under the problems of number 4 above. Sooner or later, the handle will flex, and the area will show a crack where the bolster-to-scale line is, because there is not an effective lock between the scales and bolster, and epoxy has very little tensile strength.

Another way to look at this is that a curved bolster-to-scale line is simply an inlay. I've done inlays, too, but full inlays are completely surrounded by metal that won't flex, and this is only applicable on small knives not expected to see any forces, or of limited durability. And the bolster method done this way is much weaker than a full inlay on a small folding knife, where this is reasonable. Doing this on a large knife does it no good.

This is why I choose to dovetail all bolsters, whether single, double-ended, mid-bolstered or otherwise. It's the best choice and my clients simply expect the very best.

Though I've used mosaic pins in my early knives (back in the 1980s), I haven't use them in many years.

Nothing screams out 1980s like giant saucer eyeglasses, parachute pants, and mosaic pins.

Some makers use domed pins, or pins that extend above the surface of the handle or bolster material to mount their fittings or handle. The technique is used most often on handle materials or bolsters, guards, or fittings that are extensively carved. The surface is convex, concave, may be textured, formed, or finished before being mounted on the knife blade or folding knife handle, so it would be very difficult to attach these materials with pins that are flush with the surface. Flush pins are a difficult affair; try making this happen in 304 stainless steel, with a fit so tight that you simply can't see the pins at all. In order to bypass this difficult process, or if the material is so soft and delicate that expanding a pin would crack it, domed pins are used. I know of at least one maker who mounts everything: bolsters, guards, handle material: everything, with domed and polished brass pins.

How domed pins are usually made: The blade is drilled (before heat treating) to accommodate the location of the pieces to be pinned and mounted to the knife. The material to be pinned is fitted to the flat of the blade, and the holes for the pin are backdrilled through the holes in the blade and through the material. The material is then sculpted, shaped, carved, and finished. Then the pins are tapped into position, and they may be lightly peened (or not, if the material is delicate) and then a doming tool is used to round over the surface of the pin. Sometimes one pin head is formed first, and the second is formed while the formed one is being supported by a pin anvil. Doming tools are found in the jewelry trade, and they can be high speed steel or carbide carvers and sanding apparatus. Then, the pin is covered with masking tape to protect the handle material from swarf and abrasion, and the domed pin is polished. Because the polishing may affect the carved material, domed pins are often made of softer metals (like brass) that are easy to polish without affecting the material underneath.

This is not necessarily a bad thing; but like all parts of handmade items, there are costs to pay and a specific application that should be noted.

I'm not saying that domed pins should be prohibited, and I know of at least one maker who uses domed pins to mount everything: bolsters, guards, handles, and sheath fittings. His knives all look like they are studded with tiny brass buttons, and stylistically this detracts from the heavy carving of the damascus, horn, ivory, and bone that he does. Little brass protrusions abound, and evidently, he has a following for this type of mounting arrangement, so someone likes it.

Domed pin mounting may have purpose and it's certainly well-known in the jewelry trade, and I may even use it if my project style and necessity of mounting requires it. But it is not a mount for a durable, permanent, long-lasting and tough knife fitting and handle, and should be used sparingly, not as a default mounting method.

Occasionally, I get asked to make a knife that is all black, that is, with a blued blade and blued bolsters. The bolsters can only be made of low carbon or mild steel to be cold blued; they can not be stainless steel. While there are chemical baths to blue stainless steels, they are expensive and unreliable, so I don't use them and so there is no way to darken the stainless steel bolsters. Bead blasted, the stainless steel bolsters will appear a flat gray.

I have made carbon steel bolsters in the past that are cold blued, but the care factor was extreme to prevent rust. The blade is not so much of a problem because it is hot blued (deeper penetration), and it does not have a hand wrapped around it like the bolsters do. Hands are acidic, and just one fingerprint left on low carbon steel for a while will start to rust. So, while there are some knives on my site that have cold-blued carbon steel bolsters, I wouldn’t recommend it because of the care factor.

You might ask why I don’t hot blue the low carbon steel bolsters. The bolsters are permanently attached with zero-clearance pins to the tang. Then, the bolsters and handle are finished together, for a tight, secure, bedded fit. If the knife were put in the bluing bath after the handle is mounted, the superheated caustic bath would destroy any handle material and ruin the bluing bath. So, the only bluing or treatments that can be done to steel bolsters is after the handle finishing, and that’s a carefully applied cold blue on a non-chromium (carbon steel) bolster. Often, this cold blue is not black, just a dark gray, and must be continually reapplied. The color sometimes looks blotchy, uneven, or spotty.

One option is to screw the bolsters to the tang, mount the handle material, finish it, then remove all the fittings (handle and bolsters), blue them, and then reassemble. This would only be recommended on folding knives or art knives, not heavy duty knives as the mechanical fit of screws is not as strong and secure as zero-clearance pinned bolsters. The handle-bolster junction would have to be dressed and smoothed a bit, creating a less than bedded fit. Not recommended on heavy duty tactical or combat knives.

Another option is nickel silver. The nickel silver bolster (and pins) can be darkened with off-the-shelf cold bluing sold to touch up firearms. This finish is not as dark as hot bluing steel, and it does not last as long. But the knife owner can easily touch up or re-apply the cold bluing as he sees fit. Nickel silver is expensive, and the cost has risen dramatically in the last years, so expect to pay more for this type of bolster. Since nickel silver is softer than any steel, it will rub and scuff more often and more easily so will have to be touched up more often. Of course, be aware that people with nickel allergies should not have this material on any utensil!

If a military client requires black all around, he might be able to apply a temporary coating of spray camouflage paint, to be removed after his service duty or tour. I don't recommend coatings long term on any knife, they can hide flaws, imperfections, or fractures, and might accelerate corrosion. See more on my FAQ page at this bookmark, and on my Blades page at this bookmark.

IMPORTANT NOTE! In about mid-2016, through many trials and development experiments, I came up with a process that can produce a dark, non-reflective, near-black durable patina on stainless steel bolsters and blades. This is a limited process, and can only be used on certain types of stainless steels, handle materials, and knives. This darkening agent creates a flowing, dark pattern I call "Ghost Slate." I use this process on some of my elite counterterrorism knives in my "Shadow" line. You can learn more about this at this topic link on my "Counterterrorism Knives" page.

For the bolster, what I've found that works best is pin attachment. The bolsters are pinned to the tang of the knife blade with zero clearance pins, heavily peened in place. The pins swell in position, making them impossible to remove. In fact, the only way to remove the bolster is to grind it off the tang. When done right, this creates a near seamless fit of the bolster to the tang. How many holes and of what diameter are determined by the use of the knife, the cross sectional area, and the thickness of both the bolsters and the tang. I don't solder most bolsters. Soldering creates localized heat that may affect the blade temper. Unless acidic soldering flux is removed from any area between the bolster and the tang, it can lead to corrosion of the knife tang and eventual failure. And it is a step that is not necessary, particularly on high chromium steel blades and bolsters. It must be working well, in over 3000 knives over 30 years as of this writing, I've never had one fail.

Any time you have moving parts in contact with each other, a wear pattern will emerge. On the modern knife with a uniform or mirror finish, this becomes visible. The bolster of any knife is the area where the sheath (either leather or kydex) grips the knife to hold it secure. So every front bolster scuffs, and this is normal. Changing the material can help somewhat, but even mirror polished high chromium stainless steel bolsters will scuff. There simply has to be some area where the tension of the sheath can be applied to the knife to hold it firmly and safely, and gripping the front bolster is better than gripping on the blade. Sometimes, engraving the front bolster helps this a bit, only because it isn’t as noticeable because of the engraving.

The best way to limit this may be with a locking sheath. The locking sheath relies upon the lock to maintain the knife in the sheath, and not tension of the sheath on the bolster faces. So, though the bolster helps hold it in position, there is less stress on the bolster face, and less scuffing. There is usually some scuffing on every knife when inserted and removed continually from the sheath. In the locking or kydex sheath, this sometimes shows up on the blade as very fine lines usually on the spine of the knife. This too, is normal. If needed, the scuffing can be quickly removed from a mirror polish with a fine buffer and green chromium rouge. It doesn’t affect the value of the knife unless it has deep scratches, and those could be due to embedded sand or grit from use.

The scuffing can be more obvious in a bead-blasted bolster or blade. That is because of the uniformity and light reflection from the finish. This is not easily corrected, only re-blasting the entire handle will remove it, and it will promptly return. On bead-blasted or tactical and field models, this is usually not an issue, for each knife wears the marks of its use, age, and expeditions. Many owners are proud of the marks on their knives, the stain of use, the scratches of combat with the elements (or direct combat), and most knives age gracefully. I have clients that prefer brass and high carbon alloys (non-stainless) steels just because of the patina that these steels wear after decades of use.

There are other collectors who wish for their knives to remain pristine. Like a fine collector’s firearm, the knives are never used, only stored and admired. They maintain the highest value, of course, and are never (hopefully) stored in their sheaths. Their pleasure is derived from owning an investment, and ultimately a collection, rather than using the fine tool in excursions, combat, or daily use and routine.

So, don't worry about a little scuffing on your knife. It shows that it has been pulled from the sheath, used, admired, and returned with frequency. It's handled, and that is what a knife was meant to do. See this additional topic about scratches on knife blades on my Blades page.

A guard is completely different from a bolster. It is created to "guard" the hand from the blade, and lends itself particularly but not limited to double edged knives, daggers, and swords. In the old days, it would guard your hands from an opponents blade, but modern knife battles are rare...

Guards are made from the same materials as the bolsters listed above, and are milled and machined to fit on a reduced tang that is also milled to fit. The guard is mechanically fitted to the tang, then usually soldered in place at the shoulder. It is this fit to the shoulder of the ricasso and the cross-sectional thickness of the tang through the guard that determines the overall strength of the knife/handle junction. It is weaker than the bolster/full tang design, but there are some designs that simply cannot be made any other way. The tang of the knife is then tapped or hard-soldered or welded to a threaded rod. The handle pieces are drilled and stacked onto the tang, then the pommel (which is drilled and tapped) is screwed on. The whole assembly of the handle may take many components (I've made one knife that had over 50 pieces on a hidden tang), and is usually filled with high quality, high strength jeweler's epoxy. After the epoxy sets, the handle, pommel, and guard are ground, sanded, and finished. This design lends itself to full, rounded handles, and decorative styles like fluting, spiral fluting, and wire wrapped inlays. It also hearkens back to the days when good steel was prized for its rarity, and not "wasted" beneath handle material.

Skin handles? Handles made of skin? No. I occasionally get asked to make this style of handle; I don't do it. I don’t do the whole Japanese reproduction thing, though there are many modern makers who do. My reasons are several:

First, it's been done. I like to create new and exciting knives, with modern methods and techniques, using modern or unusual materials never before used in knife handles (like gemstone). I don't make reproduction or copy knives, and anything I do in that style would be a copy.

Second, that type of handle has very poor durability, even when made by a master. The silk or cord wrap is short lived, and will absorb oils and acids and soils and ultimately work loose, or become stained and unusable. Cord of any kind has no place on a knife handle. I talk about parachute cord wrapping knife handles on my military knives page here. This is a similar application, even worse if the material is silk, which is weak and short lived. It is expected that if the piece is handled, it will, at some time, need to be rewrapped and repaired. I like to build durable knives that don't need maintenance of any kind. Of course, I realize that most of the handles made in this traditional way are not used or handled in order to preserve the handle. That is not what I expect of my knives. The rayskin underlayment is more durable than the silk or cord wrappings, and I use rayskin inlays on my sheaths, but in my opinion it is simply not a sturdy material, especially when you compare it with hardwoods, stabilized materials, manmade materials or gemstone (the ultimate in durability and value). The way both the rayskin and cord wrappings are traditionally mounted are also short-lived.

Third, I personally don't like that type of handle. Stylistically, I don't think that it looks good on a modern knife. The first thing that comes to my mind when I see a knife handled this way is that it is a reproduction piece, a copy of an original work dated by cultural fashion and antiquity. I prefer a more modern look, my own artistic creation of a modern knife.

In the early 2020s, there started to be a lot of interest in knife handle materials made of copper or assemblages of metals. Many of these are called superconductors. It's a neat word, but know this is hijacked from science, just to make this material sound better. Again, sales are the key, and copper wire scrap fetches a large price. What these materials actually are is copper reinforced with titanium or sometimes niobium. They can be cut to form an interesting geometric pattern between the various metals. They aren't actually "superconductors" unless they are cooled to near absolute zero. This never happens with a knife handle (thankfully), so in essence, they are actually just copper with titanium, and derive their mass from the copper.

Metal handles are nothing new; metal handles in swords and large daggers go back literally millennia. People don't often think about this; even historians miss the boat on why these early handles were so often made of metals. It isn't because of durability or beauty; it's mostly because of weight.

Solid metal handles weigh a lot. Take copper, for instance. It's got three times the specific gravity (8.95 SG) of jades (3.0 SG) and almost four times that of jasper (2.5 SG). A heavy handle would serve well to counterbalance a large, heavy blade, like a sword blade, making the feel and heft of the blade more balanced and less blade-heavy.

However, a sword is not a hand knife. In a hand knife, a primary consideration is the balance (detailed on my "Six Distinctions" page). A heavy, overweight handle makes a knife feel lightweight in the blade, weak, and ineffective. This is the first problem with metal component handles. It's not an insurmountable issue, but it is an important one that is based first in the material choice.

Another problem with copper or copper alloy or copper component handles is the copper! Copper is very, very soft. It will scratch and wear at the first opportunity, scuffing and abrading away. Understand that aluminum has a Brinell hardness of about 70, but copper has a Brinell hardness of about 45! Copper is softer than aluminum! Bronze is about twice as hard as copper, and so is brass. Copper is a 3.5 on the Mohs scale (comparing with stone), and is somewhere between calcite and fluorite. Calcite is far too soft to be used for knife handles or jewelry of any kind, and fluorite can only be used in heavily protected inlays with reinforcements on light duty knives.